PRODUCTS

CAPABILITIES

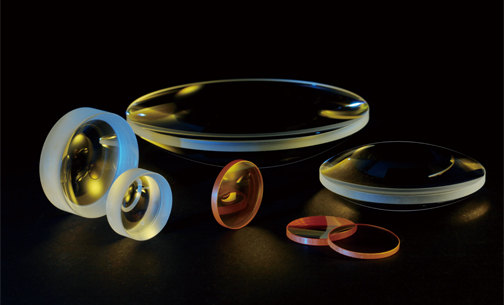

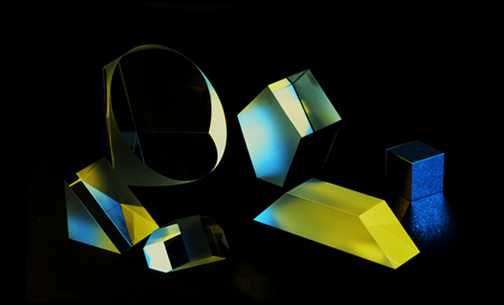

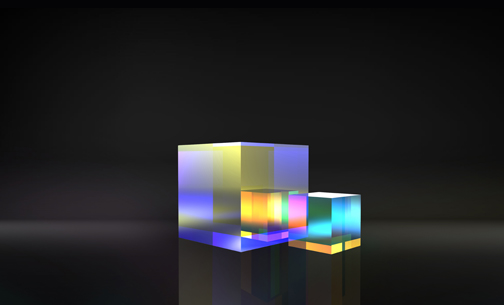

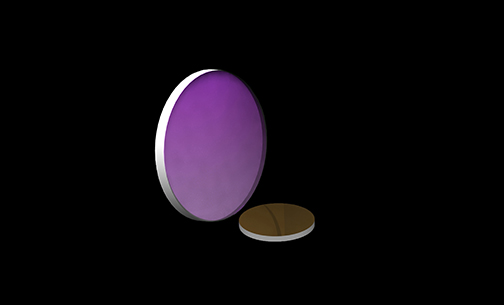

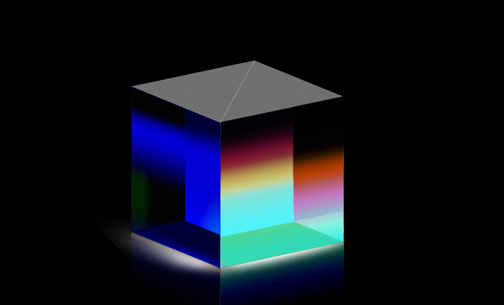

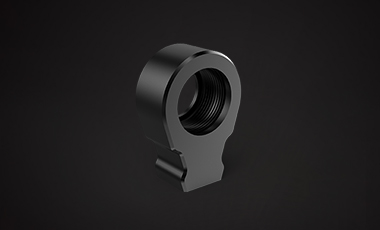

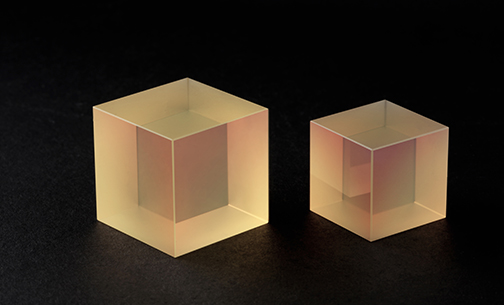

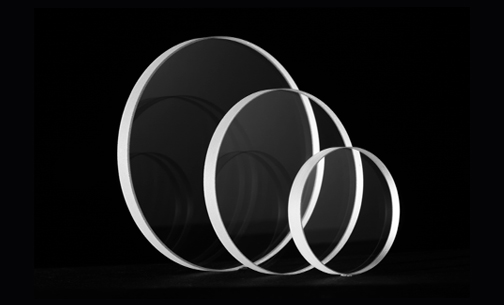

Customization of optical and optomechanical components

Customization of optical and optomechanical components

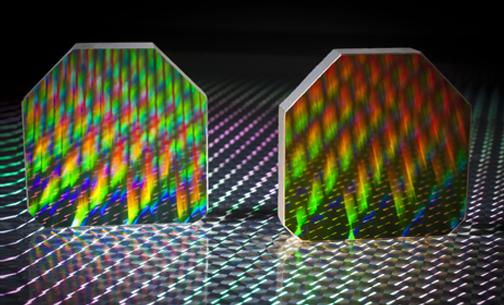

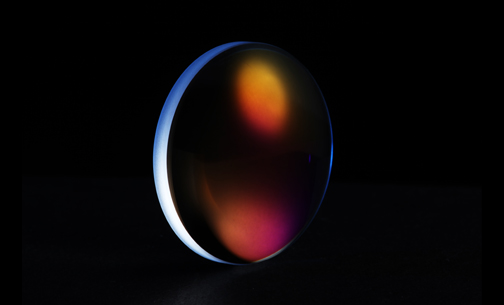

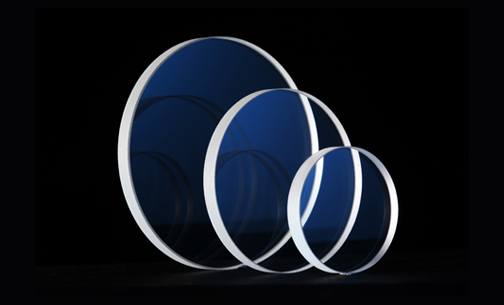

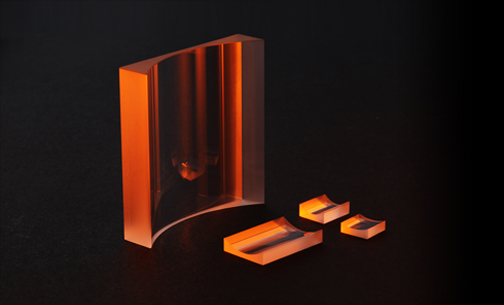

Customization of imaging lenses

Customization of imaging lenses

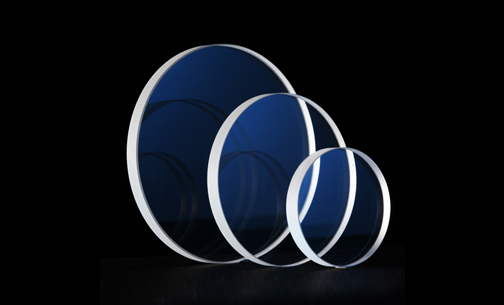

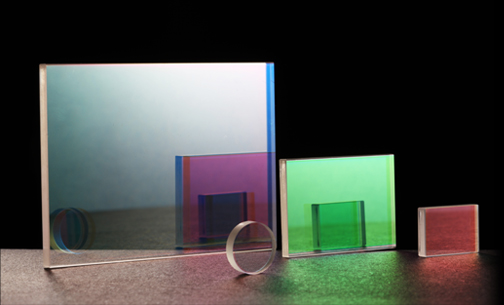

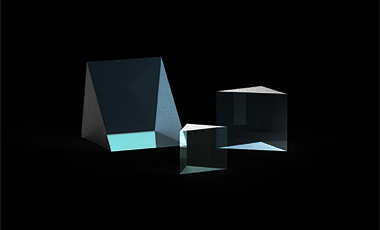

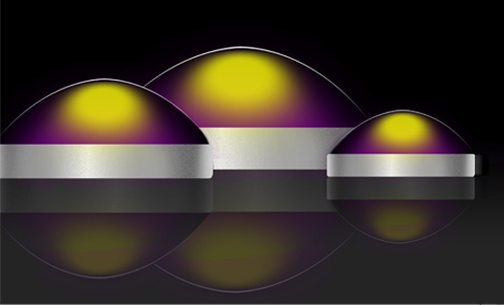

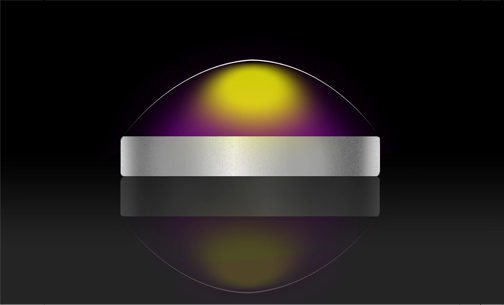

Customization of optical coating

Customization of optical coating

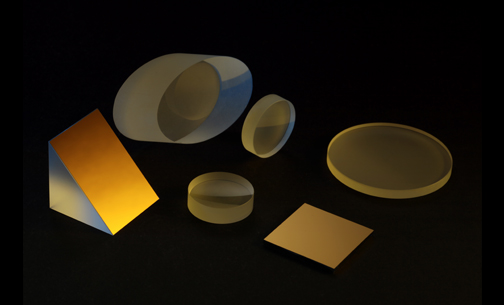

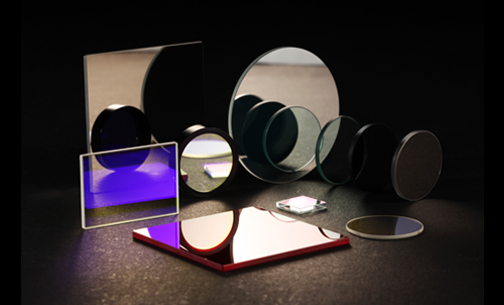

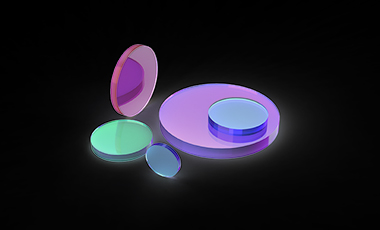

Customization of optical and optomechanical systems

Customization of optical and optomechanical systems

Customization of optical and optomechanical components, imaging lenses, optical coating, optical and optomechanical systems.

CONTACT US

Having professional testing equipment and a rigorous technical team

Having professional testing equipment and a rigorous technical team

Testing equipment includes: German TRIOPTICS OPTISPHERIC 2000 AF focusing instrument, ULTRA-SPHEROTRONIC ball diameter instrument, PRISMMASTER HR MOT goniometer, AmericanZYGO INTERFEROMETER interferometer, and PEKIN-ELMER LAMBDA 950 spectrophotometer

Testing equipment includes: German TRIOPTICS OPTISPHERIC 2000 AF focusing instrument, ULTRA-SPHEROTRONIC ball diameter instrument, PRISMMASTER HR MOT goniometer, AmericanZYGO INTERFEROMETER interferometer, and PEKIN-ELMER LAMBDA 950 spectrophotometer

Analysis expertise covers ZEMAX, SOLIDWORKS, MATLAB ® etc.

Analysis expertise covers ZEMAX, SOLIDWORKS, MATLAB ® etc.

Professional support based on your needs

Professional support based on your needs

Having professional testing equipment and a rigorous technical team, testing equipment, analysis expertise covers ZEMAX, SOLIDWORKS, MATLAB etc., professional support based on your needs.

CONTACT US

Over 20 years of design experience in optics, optomechanics and optical lenses

Over 20 years of design experience in optics, optomechanics and optical lenses

Analysis expertise spanning ZEMAX, SOLIDWORKS, MATLAB® and more

Analysis expertise spanning ZEMAX, SOLIDWORKS, MATLAB® and more

Design optimized for integration and high yield

Design optimized for integration and high yield

Over 20 years of design experience in optics, optomechanics and optical lenses, analysis expertise spanning ZEMAX, SOLIDWORKS, MATLAB and more, design optimized for integration and high yield.

CONTACT US

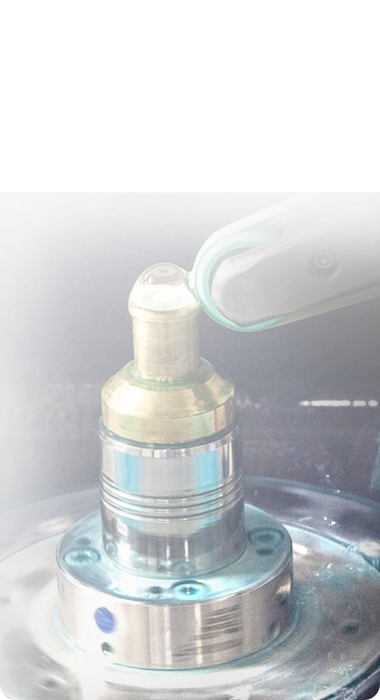

Over 20 years of manufacturing experience in optics, optomechanics and optical lenses

Over 20 years of manufacturing experience in optics, optomechanics and optical lenses

Over 20 years of manufacturing experience in optics, optomechanics and optical lenses

CONTACT USHOT SALES

VIDEO